When I tried to curl the bucket on my front end loader, hydraulic oil would spurt out the top of the control valve and the bucket wouldn't curl. The boom worked fine and oil didn't spew out the control valve when I lifted it up or down so I continued to work with it like that and I got what I had to get done, but I knew I had some work to do when I got it home.

When I got home, I looked up the parts in my parts manual and did some research online at http://www.tractorbynet.com/ and decided to attempt to replace the seals on the loader control valve and see if that worked.

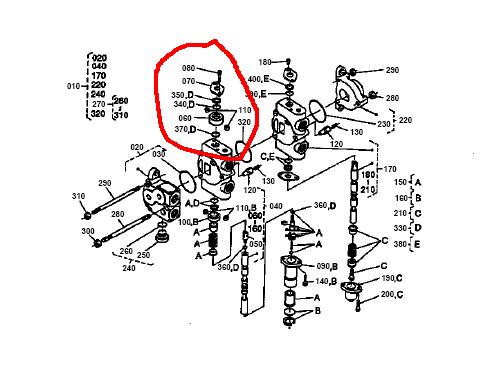

Here's the part's diagram (you can get these free online).

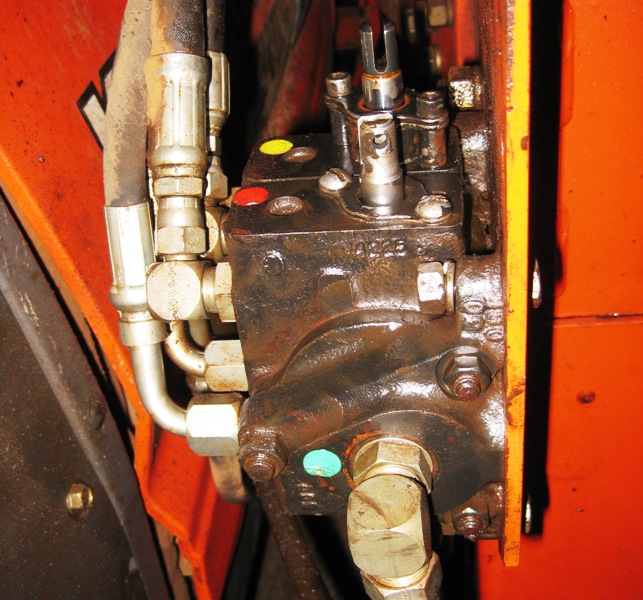

Here's a picture of the control valve for the loader.

Here's a picture of the control valve for the loader. When I bought the parts to replace the seals, they came as a complete seal kit that included everything for the top and bottom of the cylinder rod. Only the top was leaking, but I figured I had the parts to replace the bottom seal, so I might as well go ahead and do it. What I didn't expect, was that when I took it apart was to be chasing springs and ball bearings across the barn floor! Here they are after I collected them.

When I bought the parts to replace the seals, they came as a complete seal kit that included everything for the top and bottom of the cylinder rod. Only the top was leaking, but I figured I had the parts to replace the bottom seal, so I might as well go ahead and do it. What I didn't expect, was that when I took it apart was to be chasing springs and ball bearings across the barn floor! Here they are after I collected them. I have a friend who works on heavy equipment for a living, and it's always nice to be able to call him when a crises arises. The solution? Vaseline! After cleaning everything up, I just globbed some vaseline on the ball bearings and that held them in place while I slipped the rod back into the sleeve it goes in. He also said that the vaseline is actually good for the hydraulic system and will clean and lubricate it.

I have a friend who works on heavy equipment for a living, and it's always nice to be able to call him when a crises arises. The solution? Vaseline! After cleaning everything up, I just globbed some vaseline on the ball bearings and that held them in place while I slipped the rod back into the sleeve it goes in. He also said that the vaseline is actually good for the hydraulic system and will clean and lubricate it.

Well, that's it as far as the pictures go. Not too exciting of a repair from that standpoint. I got everything back together after replacing the seals and started the tractor up and picked up the bucket and tried to curl it and nothing. Oil wasn't spurting out the top of the control valve anymore, and the loader boom would raise and lower, but the bucket still wouldn't curl or dump.

I did some more reading online and decided to swap the hydraulic hoses out to see if I could isolate the problem. I swapped the hoses that controlled the boom going up and down with the hoses that controlled the bucket curl and dump. I fired the tractor back up and Wallah! I picked up the loader boom about 3 feet off the ground and then tried the bucket. The bucket curled and dumped fine using the other control valve, I went to pick the bucket up a little farther and BOOM!! Hydraulic oil exploded everywhere! Upon closer inspection, one of the hydraulic hoses feeding the control valve now had about a 3" split in it. The quick disconnect had popped off as well for good measure! Now I pretty much knew that the problem was in the control valve. Now the loader boom wouldn't come down and it was stuck about 5' in the air. I disassembled that control valve and was able to get the loader lowered with a little persistence and about a gallon of hydraulic oil puddled on my barn floor.

As I disassembled the control valve, it seemed like there was an o-ring down in the valve where it shouldn't be. If you look closely at the picture of the control valve I posted above, the bolts that are in the control valve that wasn't working properly were not factory spec (note the flat head screwdriver heads) and as about everything that I run into problems with on this tractor, it looks like the previous owner had been in there first. Sure enough, they had used some thin 0-rings and the wiper wasn't OEM either. I replaced the seals and had everything back together and replaced the blown hydraulic hose and everything was ready to go.

Started her up and the hydraulics were completely dead. The 3 point lift didn't work, and nothing on the loader worked. Pretty scary.

I did think that with all the hydraulic oil on the floor, there might not be enough left to operate the hydraulics, so I ran out and bought some more hytran fluid (most tractors use the same oil for both their hydraulic system and the transmission fluid). I added about 2 gallons and I started it up again and the hydraulics were still completely dead. I started to feel sick. I knew that it couldn't have leaked 2 gallons since it was working last night. I started adding some more and noticed the level start to register on the sight glass. At about 2.5 gallons I was almost to the middle of the sight glass and I started her back up. (At the time I bought it, I was thinking the 5 gallon bucket of oil was overkill but that's the only size they had it in).

After a second of nothing, the 3 point lift sprang to life!! Then the loader started working, and it raised and lowered the boom, and curled and dumped the bucket!!!!!

I ran it through several cycles and everything seemed fine. I didn't take it out and actually try to dig or put any extra pressure on it, but I'm thinking there must have been something blocking or jamming that control valve cylinder and that was the problem the entire time. So, a few extra hours of repair time, but the seal kits cost less than $50 and everything else including the 5 gallon pail of hytran was about another $50 so a pretty inexpensive repair in terms of $.

That's it from this end. Hopefully nothing else breaks anytime soon!!

Nathan

No comments:

Post a Comment